XCES – Advanced Self-Sharpening Ground Engaging Tools (GET)

Technical Overview

GBT Global’s XCES series represents a new generation of self-sharpening Ground Engaging Tools engineered for high-abrasion and high-impact environments. Developed using proprietary geometric shaping and metallurgical hardening processes, XCES Teeth maintain a consistent cutting edge throughout their wear cycle, delivering substantially longer service life and superior material penetration relative to conventional cast teeth.

Technical Features & Design Advantages

1. Self-Sharpening Geometric Profile

-

Designed with a patented dual-bevel wear pattern that forces progressive controlled erosion.

-

Maintains a sharp chisel point without manual reshaping or edge maintenance.

-

Reduces cutting resistance, improving bucket fill factor and cycle efficiency.

2. High-Strength Alloy Composition

-

Manufactured using a proprietary alloy steel blend optimized for:

-

High abrasion resistance

-

Resistance to deformation under impact loading

-

Thermal stability under continuous duty cycles

-

-

Heat-treated using a multi-stage quench and tempering process to achieve a balanced hardness-to-toughness ratio.

3. Extended Wear Life (50%–100% Increase)

Independent field use in large-scale mining operations consistently shows:

-

50–100% improvement in wear life versus standard cast or welded teeth.

-

Less rounding and mushrooming of the tooth tip due to self-sharpening geometry.

-

More stable penetration force over the lifespan of the tooth.

4. Improved Penetration & Lower Fuel Consumption

Because the tooth remains sharp, operators experience:

-

Lower breakout force requirements

-

Reduced wheel spin (especially on <5T loaders)

-

Lower hydraulic system strain

-

Fuel savings due to more efficient cycle times

-

Better tire longevity because machines work with less force and slippage

Compatibility & Installation

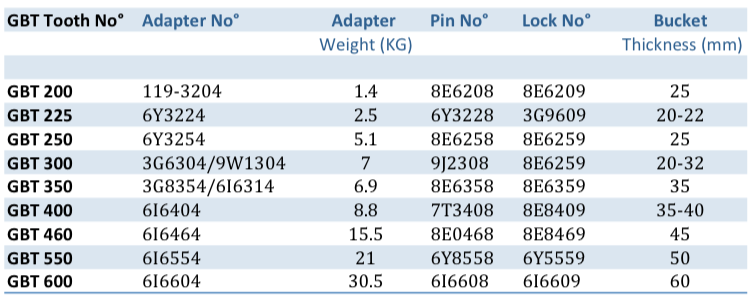

Adapter Compatibility

XCES Teeth are designed to fit standard heavy-equipment GET systems, including:

-

ESCO-style adapters

-

CAT-style adapters

-

Universal GBT adapters for mixed-fleet mining operations

Machine Applications

-

Loaders (small- to large-size loaders)

-

Excavators (20–120 ton class)

-

Scrapers (all major earthmoving configurations)

-

Suitable for both front-end bucket and backhoe configurations.

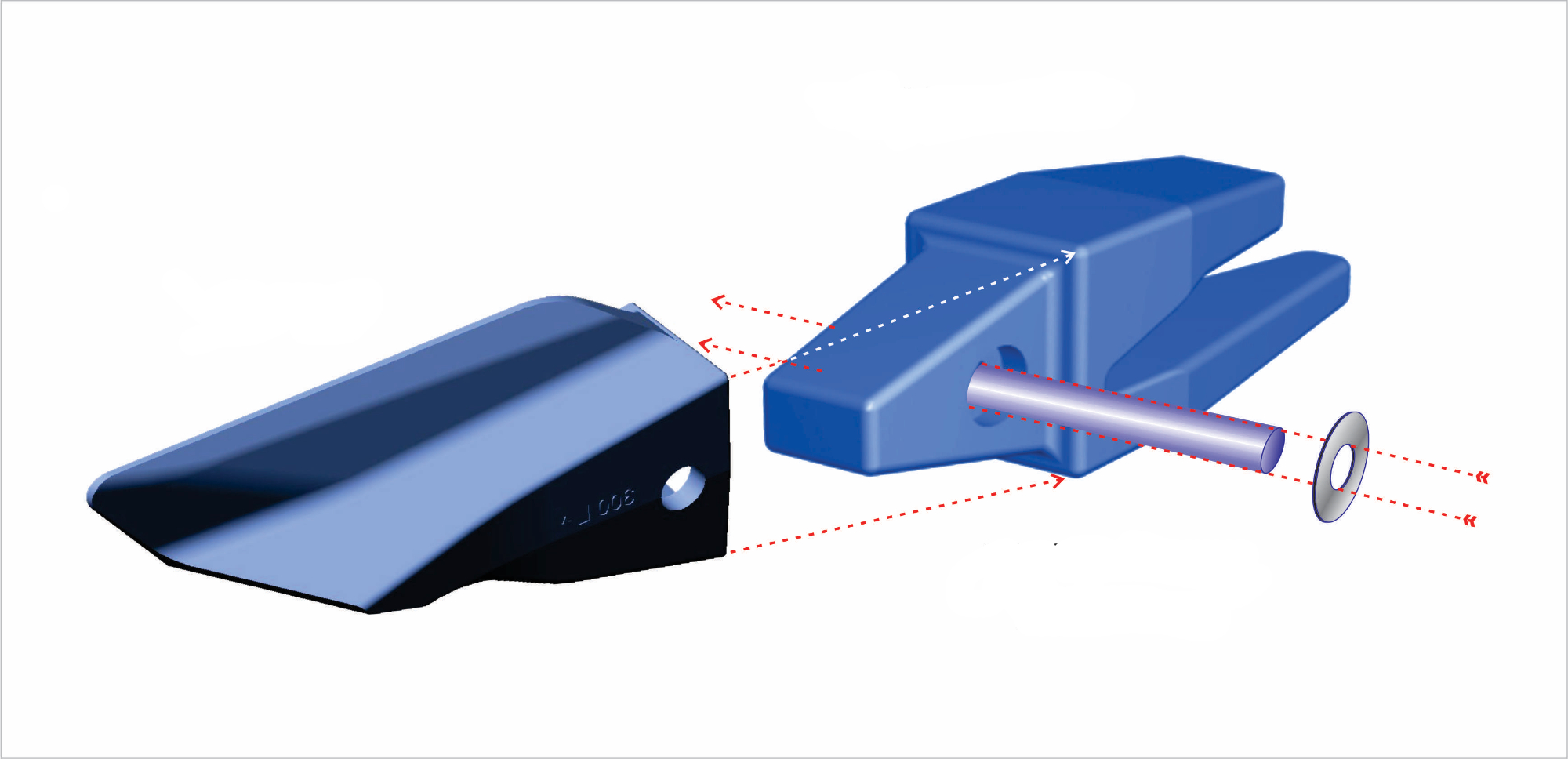

Installation Notes

-

Designed for quick-change systems with pin-and-retainer configurations

-

Optimized tooth-to-adapter fit to reduce vibration and “tooth play”

-

Reduced risk of adapter wear through minimized backlash

Increased Productivity in Harsh Environments

Optimized for:

-

Granite, basalt, and other high-compression aggregates

-

Iron ore, copper, nickel, lithium, gold, phosphate mining

-

Frozen ground and compacted overburden

-

Quarrying and heavy construction environments

The reduced downtime from fewer changeouts translates directly to operational gains, particularly in remote mining sites where tooth replacement has high labor and logistical costs.

Right- & Left-Hand Engineering Design

XCES Teeth are available in mirrored configurations:

Right-Hand & Left-Hand Tooth Profiles

-

Engineered to create a centralizing material flow path inside the bucket.

-

Improve bucket load distribution, reducing sidewall wear.

-

Increase material capture by forming a natural scooping geometry, improving bucket fill factor by 3–9% depending on material.

Summary of Technical Advantages

-

Patented self-sharpening wear geometry

-

Proprietary alloy steel with high-impact resistance

-

50–100% increased wear life

-

Lower machine fuel consumption

-

Improved cycle efficiency and fill factor

-

Reduced wheel spin and tire wear

-

Compatible with major GET systems (ESCO, CAT)

-

Ideal for high-abrasion mining and construction environments